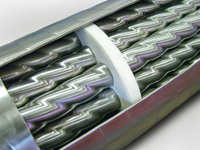

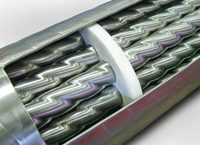

Corrugated Tube Heat Exchangers

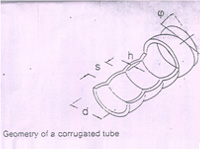

We have developed high performance corrugated tube/shell heat exchangers, which provide increased turbulance & in turn higher heat transfer coefficient even at low Reynolds number. In corrugated tube/shell heat exchangers higher turbulance is achieved due to programmed deformation (i.e. Corrugation) of tube/shell, which induces spiral fluid flow compared to plug flow in smooth tubes/shell. As on today we have designed & supplied at least 500 (Five Hundred) compact corrugated heat exchangers for applications like highly viscous liquid heating/cooling & evaporation of liquids, which involves two phase flows and also for condensation & with operating pressure as high as 35.0 bar.

We have developed high performance corrugated tube/shell heat exchangers, which provide increased turbulance & in turn higher heat transfer coefficient even at low Reynolds number. In corrugated tube/shell heat exchangers higher turbulance is achieved due to programmed deformation (i.e. Corrugation) of tube/shell, which induces spiral fluid flow compared to plug flow in smooth tubes/shell. As on today we have designed & supplied at least 500 (Five Hundred) compact corrugated heat exchangers for applications like highly viscous liquid heating/cooling & evaporation of liquids, which involves two phase flows and also for condensation & with operating pressure as high as 35.0 bar.

Advantages Of Corrugated Tube Heat Exchangers

- Improved heat transfer coefficients, hence compact.

- High-induced turbulence causing much reduced fouling, hence steady performance over a long period of time.

- High working pressures & temperatures possible.

- Modular designs for small applications with flexibility of increasing duty as required.

- Easy to install.

- Virtually maintenance free.

- Low-pressure drops & no gasket failures compared to PHE.

- Low capital cost compared to PHE/SHE.

- Designed for easy maintenance/service compared to PHE/SHE, hence minimum downtime.

- Most suitable for heat sensitive products as no localized heating.

- Can be installed vertically, inclined or horizontally.

- Since corrugation induces flexibility, generally external bellows are not required i.e. built in expansion/contraction capability.

- Suitable for process fluids with particulate matter.

Major clients :

- M/s. Godrej Industries Ltd, Mumbai & Valia.

- M/s. Aurobindo Pharma Ltd., Hyderabad.

- M/s. IFFCO (Malaysia) Sdn. Bhd.

- Reliance Ind. Ltd.